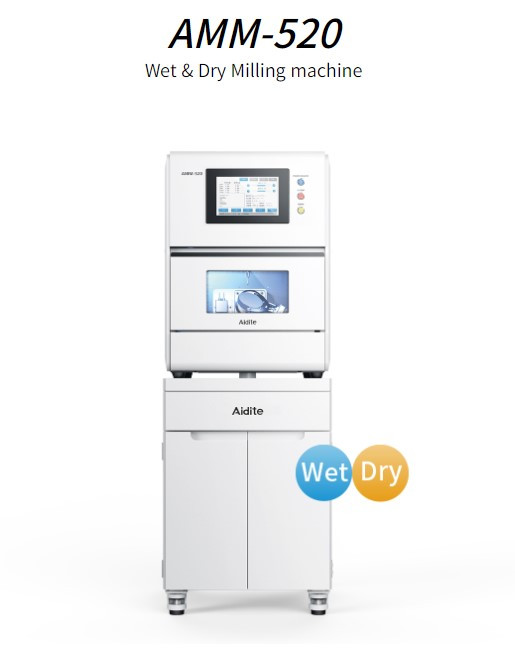

Product Description

AMM-520 is a wet and dry integrated multi-functional milling machine, with a stable structure and a variety of fixture combinations, meeting different production needs. Denture, bitesplint, snap on smile, surgical guide, partial framework, crown and bridge, veneer, inlay, post and core, screw-retained bridge (a separate nesting module needs to be added for implant case), custom abutment.

Machine size |

590×730×820(mm) |

Weight |

180Kg |

Tool changer |

10 |

Number of axes |

5 Simultaneous Processing |

Milling mode |

Wet and dry |

Material thickness |

10-35mm (round disc) |

Accessories |

Work table, water cooler, water tank |

Repeat positioning accuracy |

± 5um |

Linear drive system |

Linear guide and lead screw |

Rotary drive system |

Harmonic reducer |

Control system |

Embedded CNC system and AC bus servo motor |

Millable material |

Zirconia, PMMA, HPP, PEEK,Titanium disc, wet milling restoration material, denture, premill |

Processing time |

Single crown ≤15min, Premill ≤20min Wet milling restoration material≤20min, full denture≤3h |